VÖGELE SPARE PARTS

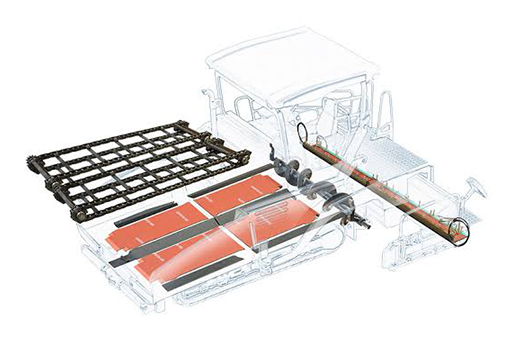

Wheeled and tracked pavers of the SUPER series are today one of the core products of Joseph VÖGELE AG. But feeders of the series POWER FEEDER and screeds are also produced by VÖGELE AG.

Vögele started with the construction of parts for the railway like e.g. railway points or rails. It was not until the end of the 1920s that Vögele started to build road construction machines, as road transport was increasingly used alongside the railway.

WIRTGEN SPARE PARTS

At the heart of the world famous WIRTGEN road milling machines are the milling drums, designed and manufactured in our Windhagen headquarters.

In the standard product range, WIRTGEN offers an extensive number of optional drums that help the customer to perform many applications in the surface processing, as well as performing recycling work or when cut mining hard rock. Almost every day we respond to individual project enquiries with appropriate solutions that require the use of special milling technologies.

HAMM SPARE PARTS

In the oscillation drum masses turning in the same direction, produce one moment around the drum axle. The ment changes its effect direction during a turn of the mass (forward and reverse), so that the oscillation drum movement is created. Here thrusts are introduced into the soil. With oscillation clearly lower resonances are generated than with the vibration. It only causes up to 10% of the stress exerted by vibrating compactors.

Oscillating rollers do not “use up” their energy to create undesired vibration of the surroundings but transmit it purposefully into the material to be compacted – exactly where the energy is needed.

Otto Group 2020 © Tüm Hakları Saklıdır Metaforya